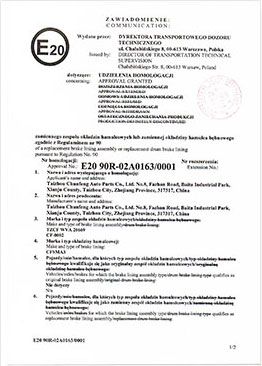

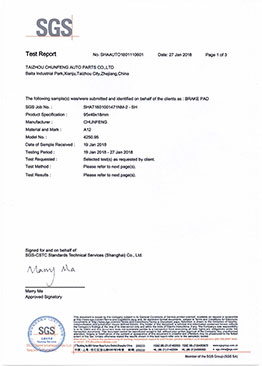

As an experienced brake parts manufacturer, we have been specializing in the design and manufacture of brake pads and brake shoes since 2005. With optimized material mixtures and production process, our products are manufactured with high quality, making sure they are certified by TS16949, ISO9001, ECE R90, etc.

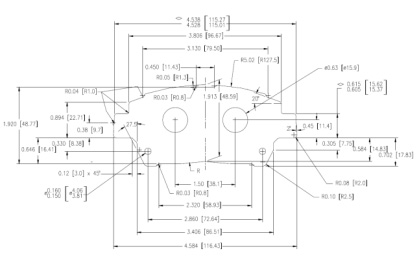

The brake pad can be designed and developed according to the original product to well match the original braking system.

This workshop is equipped with fully automatic hot presses featuring stable temperature and pressure control, ensuring high consistency in quality. An annual production capacity of brake pads reaches up to 3,000,000 pieces.

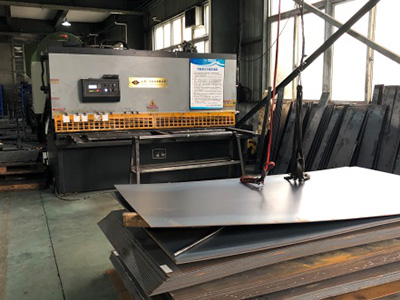

Metal shearing machines and punch presses are adopted to achieve an annual production capacity of backing plate up to 5,000,000 pieces.

In order to provide products with high quality, strict testing will be made from material to finished product using a complete set of testing equipment. The same material in different batches needs to be tested before using, ensuring quality consistency. The size of backing plates will be measured several times to achieve high accuracy. After hot pressing, finished products will be randomly chosen to undergo various tests including bonding strength between backing plate and friction material, friction coefficient.